Floating Pontoons

Innovative. Eco Friendly. Reliable

About

Construction made of floating pontoons allows to carry heavy weights and is robust against external influences: temperature, humidity, damage and micro-organic .

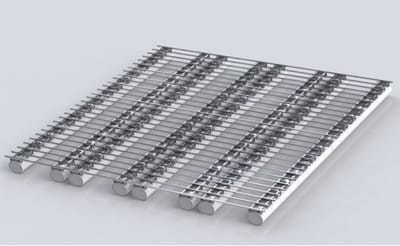

Pontoons contain a number (two and more) of floats interconnected by a rigid frame made of aluminum or steel.

Features

Matherial

Each float has an elliptical (1400 x 1140 mm) form tube split to a number of fully hermitized compartments made of the material called Polypropylene-Copolymer design.

Design

This material has unique mechanical properties. It is lighter than aluminum by weight and at the same time - stronger in relation to mechanical impacts and chemistry attacks. The ellipse form has much higher acceptable weight load than round form one.

Capacity

Each running meter of the float may keep afloat 575 kg (when the draft is 0,52 m). Means that per 12 m length the deadload is 6233 kg (own weight of 12 m float is 667 kg). Maximum possible deadload for 12 m float is 11 ton. The standard 12 x 6 m platform-module shown below may carry up to 22 ton

Team

Jonas Bickus

Founder and CEO

Dmitry Melnikov

Engineer and Designer

Alex Redkin

Supply Chain and Marketing

Services

Production

Oksis has made a number of diversified tests and worked out a complete production chain from materials purchase till complete production of various purpose floating platforms. At least three know-how were invented by Oksis engineers additionally to the initial one. Floats may be produced in versions for standing, towing, self-propulsing use. May be used for: - Accommodation facilities, - Ancillary buildings, warehouses, medical aid points; - Solar panel fields (as well as floating power generation units); - Evacuation towed platforms; - Quickly arrangeable mobile bridges, crossings and docks.

Equipment

Internal float’s compartments may be used for equipment placement (tanks, watermaker/purifier, power generator etc.) to ensure the autonomy of any object placed on the platform. The sole UV-resistant Polypropylene-Copolymer material manufacturer got chosen for the production. This is material called “Polystone”, the only accepts minus 30 C temperature without changing its mechanical properties. Means, that the float (or pontoon) may get kept in the water all year round. Basing on modular construction, the assembling platforms may reach up to 650 sqm of total area.

Advantages

- Durability; - Heavy weight acceptability; - Damage resistance; - Lightweight; - Frost-resistance; - Manufacturability of production; - Transportability; - Autonomy of built objects (possible to reach up to 100% autonomy).